Recycled cotton may be an excellent solution to avoid water scarcity problems. It’s even more environmentally friendly than organic cotton. Sustainable apparel manufacturing benefits from its use in several ways.

Recycled cotton is a more environmentally friendly option than conventional cotton and even organic cotton. This material is made up of cellulose used in the production of clothing, shoes, and accessories worldwide.

Recycled cotton is a form of natural fibre with similar characteristics to standard cotton. This cloth is light, breathable, and quick-drying.

What is recycled cotton?

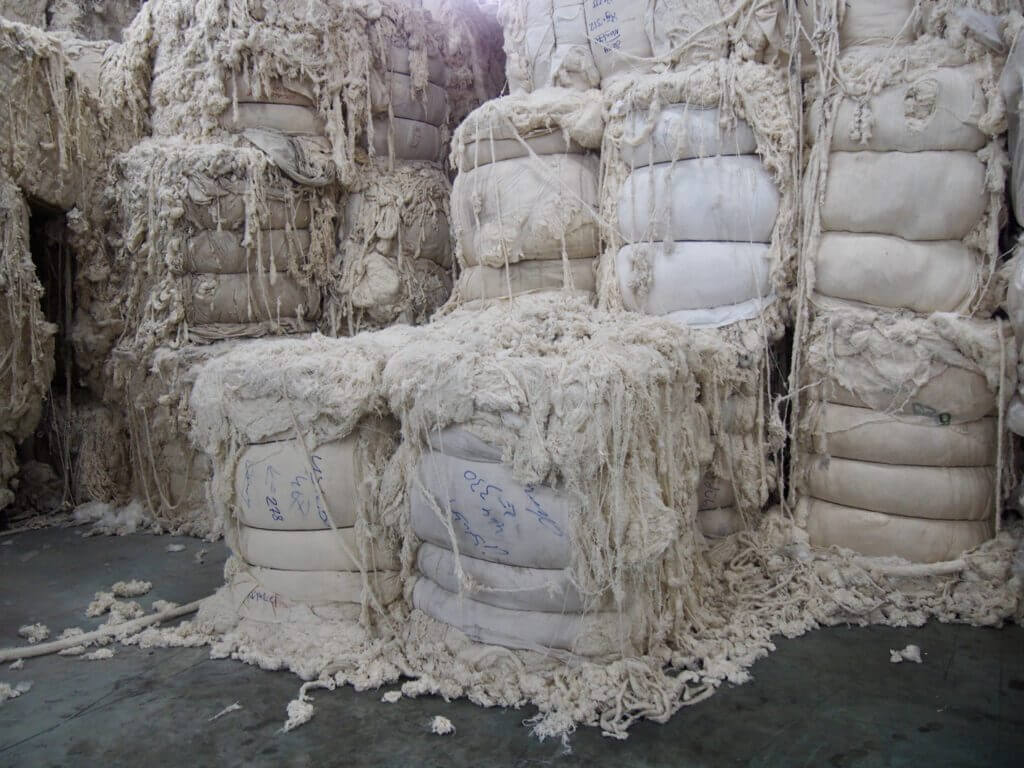

Recycled cotton is made from old or damaged cotton fabric that would otherwise be thrown away. The fabric is sorted and cleaned and then shredded into small pieces. These pieces are then spun into new yarn, which creates new fabric.

The majority of reused cotton is gathered through mechanical recycling. Fabrics and materials are first divided by colour before being sorted. After sorting, the fabrics are fed through a machine that creates yarn and raw fibre.

This process is highly abrasive, putting a lot of strain on the fibre. During shredding, it’s not unusual for fibres to break and get tangled. After the fibrous material has been collected and washed, it is spun back into yarns for future products. Recycled fibre will never have the same quality as the original fibre, which limits the number of available applications.

We may recycle cotton from old clothing or textile remnants. The quality of recycled cotton might not be as high as that of new cotton. It is sometimes combined with new cotton to improve its quality.

Recycled cotton is a more sustainable option than traditional cotton, as it requires less water and energy to produce. As a result, it saves resources and eliminates further textile waste, unlike organic or conventional cotton. This makes it an excellent environmentally friendly option, but its production is still limited.

Recycled cotton into perspective, some key facts

- The production of cotton represents c.2.6% of the global water use

- Using 1000 kg of recycled cotton instead of organic cotton can save 0.5 ha of agricultural land, prevent 6600 kg CO2 eq of emissions from entering the atmosphere, and conserve 2783 m3 of irrigation water, research shows

- Recycled cotton is mostly made out of pre-consumer cotton

- The mix of materials in textiles makes separating cotton difficult, which is a barrier to recycling

- It takes about 10,000 to 20,000 litres of water to produce one kilogram of cotton, the same as one T-shirt or a pair of jeans, according to the World Wildlife Fund (WWF)

Two sources for recycled cotton

Pre-consumer cotton

Pre-consumer cotton comprises the residue of cotton fabric scraped away during textile production. It is the most recycled form of cotton because it is much easier to recycle.

The fibre content of fabric scraps can be pre-sorted based on the cloth’s look and texture so that recycling plants don’t have to handle it as much.

Pre-consumer cotton is also more abundant and creates more volume of recyclable materials.

Post-consumer cotton

The textiles produced from cotton, including clothes, towels, and other household goods bought by customers, constitute post-consumer cotton.

It’s recyclable, but it isn’t very often because it can’t be recycled through curbside collections, and most municipal facilities lack the capability to do so.

This is because post-consumer textiles come in various colours, sizes, and textures.

It is very complicated and time-consuming to go through and sort all of the various cotton textiles that customers purchase.

Advantages and disadvantages of recycled cotton

There are several advantages to using recycled cotton in apparel manufacturing:

- Soft, lightweight, and easy to wash

- It is more environmentally friendly than traditional cotton, organic cotton, or synthetic materials.

- It requires less water and energy to produce, which saves resources and reduces greenhouse gas emissions.

- High absorbency (which makes it ideal for home or industrial cleaning cloths)

- It is made from recycled materials, eliminating waste and reducing the need for new raw materials.

- Breathable, durable, and quick-drying

- Biodegradable and recyclable, which means it has a lower environmental impact than synthetic yarn

Despite these advantages, recycled cotton still has a few disadvantages:

- The quality of recycled cotton may not be as high as that of new cotton. It is often combined with new cotton to improve its quality.

- Its production is still quite limited, so it can be difficult to find recycled cotton fabrics or products made from recycled cotton.

- It may be more expensive than traditional cotton or synthetic materials.

Recycling efforts

Today, many well-known companies have established recycling programs in their shops.

Columbia, The North Face, Patagonia, and numerous other companies encourage clients to recycle used apparel. In addition, those recycling programs often allow consumers to drop clothes from any brand.

Some of these initiatives provide consumers with discounts or points that can be used for future purchases. Patagonia also pays attention to repairing damaged clothing to extend its products’ life.

Cotton Incorporated has launched the Blue Jeans Go GreenTM denim recycling program. The Blue Jeans Go GreenTM initiative processes old jeans and converts them into insulating material. Created in 2006, the program claimed to have recycled over three million pieces of denim and diverted over 1,700 tons of textiles from landfills.

Some recycled cotton certifications

Global Recycled Standard

Control Union Certifications created the Global Recycle Standard (GRS) in 2008, and the Textile Exchange took control on January 1, 2011. The GRS is a global, voluntary, comprehensive product standard that specifies requirements for third-party recycling certification, chain of custody, social and environmental standards and chemical restrictions.

The certification is designed to fulfil the demands of businesses who want to authenticate the recycled content of their products (both completed and intermediate) as well as corporate social, environmental, and chemical policies.

It aims to establish criteria that guarantee correct content claims and acceptable working conditions and minimise harmful environmental and chemical effects. This includes ginning, spinning, weaving, dyeing, printing and stitching companies in more than 50 countries.

Standard 100 by Oeko-Tex

The OEKO-TEX® 100 Standard is a worldwide renowned label for textiles that have been subjected to rigorous testing for hazardous chemicals. It symbolises customer confidence and high product safety.

If a textile item has the STANDARD 100 label, you can be confident that every thread, button, and other accessories have been checked for hazardous substances and that the product is safe for human health.

Their testing partners examine several different compounds, both regulated and non-regulated, that may be hazardous to human health in the test.